Resista® Abrasion Resistant (AR) Valve

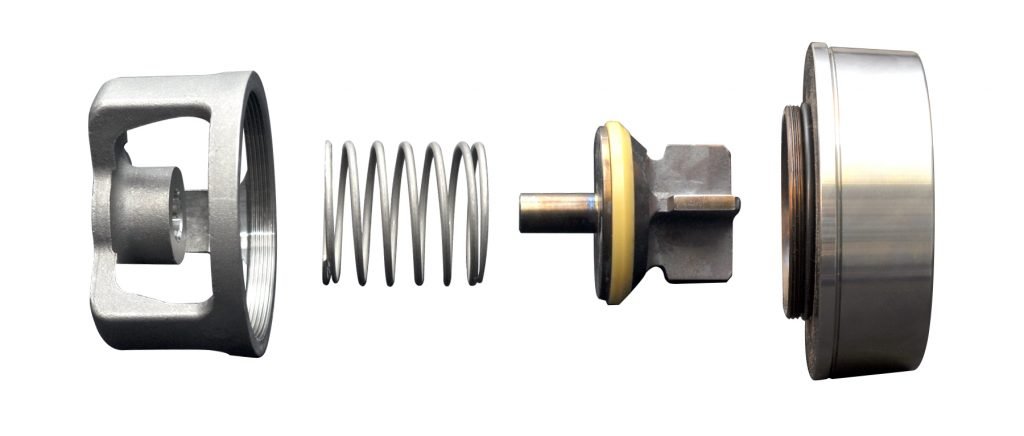

Among our diverse product offerings at Triangle Pump Components, Inc. is the Resista® Abrasion Resistant (AR) Valve, designed for applications enduring some of the heaviest wear. This valve, available in two different varieties, is ideally suited for use in pumping environments containing abrasives or small solids and high pressures.

While our standard Resista® Abrasion Resistant (AR) valve seats come in 316 Stainless Steel, they are also available in 17-4 hardened Stainless Steel and other alloys. The valve member is made of the same material as the seat, either with or without a polyurethane insert for use in temperatures below 160°F. For higher temperature applications, we provide fluoroelastomer inserts.

Resista® Abrasion Resistant (AR) Valve Technical Specifications

Triangle Pump Components’ Resista® AR valve is ideal for the most rigorous applications and pump systems. Able to pump abrasive media such as acid, hazardous chemicals, chlorine, and small solids under pressures up to 15,000 psi, this reciprocating pump AR valve is the most durable product available in today’s marketplace.

TPCI’s Resista® AR valve encompasses a wide array of sizes and is most commonly sold in:

- 316 Stainless Steel

- 17-4 Hardened Stainless Steel

- We also are capable of creating Resista® AR valves using other materials for special applications. For an abrasion resistant valve made from a special or unique material please contact us today

The valves, seats and seals of the abrasion resistant (AR) valve are composed of several materials:

- Duplex stainless

- Stainless Steel

- 8620 Alloy

- Hardfacing stellite

- Monel®

- Viton® – Fluoroelastomer (For temperatures exceeding 160° F)

Triangle Pump Components handles both high and low volume orders, as well as prototyping and specialty production. In addition to these capabilities, we offer CAD design and CAM programming services to reverse engineer and manufacture parts for our customers.o.

Resista® Abrasion Resistant Valve Part Numbers

| Gardner Denver | Valve Size | S/D | Abrasion Resistant Stainless Steel Valve Units | Series |

|---|---|---|---|---|

| PQ-2A, PS25A, PG-3, PW-3H,PW-3A TQC, GD45T, TQW | 225 | S/D | AR05A-03 | 5 |

| PS-25C, G, H, PW-3D, E, F, BLOCK F.E. | 150 | S | AR02A-05 | 2 |

| PS-25C, G, H, PW-3D, E, F, BLOCK F.E. | 225 | D | AR05A-03 | 5 |

| TA-3B, C, BLOCK F.E. | 150 | S | AR02A-14 | 2 |

| TA-3B, C, BLOCK F.E. | 225 | D | AR05A-27 | 5 |

| TA-5H, J, TA-4B,C, F, G, BLOCK F.E., GD180M | 225 | S | AR05A-27 | 5 |

| TA-5H, J, TA-4B,C, F, G, BLOCK F.E., GD180M | 225 | D | AR55A-02 | 55 |

| TA5-B, G, TA4-A, E, TA3-A, TAE-BCB, GD100, GD180L | 300 | S | AR89A-12 | 89 |

| TA5-B, G, TA4-A, E, TA3-A, TAE-BCB, GD100, GD180L | 350 | D | AR81A-02 | 81 |

| TA-5A, F, TFE, GD-200-T, F, TAEF, TDEA, TFEA, TAEBAA, T200L, GD250T | 400 | S | AR10A-18 | 10 |

| TA-5A, F, TFE, GD-200-T, F, TAEF, TDEA, TFEA, TAEBAA, T200L, GD250T | 400 | D | AR11A-03 | 11 |

| PE5-Q, R, W, X, PT-4J, K, PX-5D, E, PE-5AA, BLOCK F.E., TEE-BFA | 225 | S | AR05A-03 | 5 |

| PE5-Q, R, W, X, PT-4J, K, PX-5D, E, PE-5AA, BLOCK F.E., TEE-BFA | 225 | D | AR55A-01 | 55 |

| PQ-2B, PS-25F, PQ-2D, PS-WK, TQWABB | 225 | S | AR06A-23 | 6 |

| PQ-2B, PS-25F, PQ-2D, PS-WK, TQWABB | 225 | D | AR66A-04 | 66 |

| PA-8N, PE-5E, J, U, PX-5A, PAHAA, PA-8A, R, S, U, PE-5C | 375 | S/D | AR10A-02 | 10 |

| PT4-A, L, PX5-B, PE5D, F, G, H, K, L, T, V, Y, Z, TEE-BGB | 300 | S/D | AR89A-02 | 89 |

| TEE-BAA, TEE-BFB, TEE-BJB (TEE w/maximum flow uses AR10A-68) | 350 | S/D | AR98A-68 | 98 |

| TDD-A | 350 | S | AR98A-16 | 98 |

| TDD-A | 350 | D | AR90A-01 | 90 |

| PA-8W, PA-8X, PAHAB, PAHAC | 300 | S | AR89A-02 | 89 |

| PA-8W, PA-8X, PAHAB, PAHAC | 325 | D | AR81A-01 | 81 |

| LF5, FFFXF, Duplex | 350 | S/D | AR98A-03 | 98 |

| FCFXX, FCFXD, FCFJ, FCFC, Duplex | 375 | S/D | AR09A-30 | 9 |

| FGFXG, FDFXX, FDFXD, FDFS, FDFJ, Duplex | 400 | S/D | AR10A-05 | 10 |

| FXFXZ, FYFXX, FYFXD, FYFS, Duplex | 550 | S/D | Not Available | 21 |

| QAFB & QAFBBA | 275 | S/D | AR38A-04 | 38 |

| QAFC & QAFBCA | 225 | S/D | AR36A-10 | 36 |

| QAFC & QAFBCA | 400 | S/D | Not Available | 43 |

| GD-135, QBX, QBXA, TDDB, GD135QLP | 225 | S | AR07A-41 | 7 |

| GD-135, QBX, QBXA, TDDB, GD135QLP | 225 | D | AR07A-42 | 7 |

| Gaso | Valve Size | S/D | Abrasion Resistant Stainless Steel Valve Units | Series |

|---|---|---|---|---|

| T-10-4 | 150 | S/D | AR02A-34 | 2 |

| 3211, 3364, 3364-F, 2321 55T-3M | 175 | S | AR03A-02 | 3 |

| 3211, 3364, 3364-F, 2321 55T-3M | 200 | D | AR05A-02 | 5 |

| 3364 (Same size suction & discharge) 55T-3L | 200 | S/D | AR05A-02 | 5 |

| 3365 | 275 | S/D | AR04A-04 | 4 |

| 5350-M, 5698-M, 2913-M, 3113-M, 3088-M/MS, 2888-M | 225 | S | AR05A-28 | 5 |

| 5350-M, 5698-M, 2913-M, 3113-M, 3088-M/MS, 2888-M | 225 | D | AR50A-04 | 50 |

| 3113-H | 200 | S | AR05A-39 | 5 |

| 3113-H | 225 | D | AR05A-28 | 5 |

| 5350-L, 3113-L, 3088-L, 2913-L, 2888-L, 5698-L | 300 | S | AR89A-17 | 89 |

| 5350-L, 3113-L, 3088-L, 2913-L, 2888-L, 5698-L | 300 | D | AR80A-03 | 80 |

| 3467, 3580 | 275 | S/D | AR07A-21 | 7 |

| 3580 (Old Style) Ser. #32492 & Down | 225 | S/D | AR06A-15 | 6 |

| 3466, 3581, 3868, 3968 | 350 | S/D | AR98A-54 | 98 |

| 3582, 3969, 3670, 3869 (Serial #33036 & Down) | 400 | S/D | AR10A-06 | 10 |

| 3583, 3774, 5884, Q-350-2, Q350-5H T200-2 | 225 | S/D | AR36A-09 | 36 |

| 3671, 3673, 5885WS, 3776WS, 3673WS | 400 | S/D | AR10A-01 | 10 |

| 3672, 3670 (Serial #33037 & Up) | 300 | S/D | AR89A-17 | 89 |

| 3775, 5885, T-450-3,Q-350-3, 350Q-5M, T200-3, T250-M | 350 | S | AR98A-54 | 98 |

| 3775, 5885, T-450-3,Q-350-3, 350Q-5M, T200-3, T250-M | 350 | D | AR90A-01 | 90 |

| 3776, 5886, Q350-4, 350Q-5L, T200-4, T250-L | 400 | S | AR10A-01 | 10 |

| 3776, 5886, Q350-4, 350Q-5L, T200-4, T250-L | 400 | D | AR11A-01 | 11 |

| 601, 602 Simplex | 250 | S/D | AR06A-07 | 6 |

| 1507, 2017 Duplex | 400 | S/D | Not Available | 12 |

| 1509, 2019 Duplex | 350 | S | AR09A-12 | 9 |

| 1509, 2019 Duplex | 400 | D | AR10A-06 | 10 |

| 1654, 1742, 1755 Duplex | 400 | S/D | AR10A-01 | 10 |

| 1740 Duplex | 350 | S | AR98A-16 | 98 |

| 1740 Duplex | 350 | D | AR98A-13 | 98 |

| 1741 Duplex | 400 | S | AR10A-01 | 10 |

| 1741 Duplex | 400 | D | Not Available | 12 |

| 1743, 1753, 2651 Duplex | 400 | S/D | Not Available | 20 |

| 1844, 2244 Duplex | 300 | S | AR89A-21 | 89 |

| 1844, 2244 Duplex | 350 | D | AR98A-54 | 98 |

| 1845, 2245 Duplex | 350 | S/D | AR98A-33 | 98 |

| 1847, 1849, 1860, 2249, 1550, 2050, 1560, 1563 Duplex | 400 | S/D | AR10A-06 | 10 |

| 1848 Duplex | 350 | S/D | AR98A-54 | 98 |

| 1508, 2018 Duplex | 300 | S/D | AR89A-20 | 89 |

| 1931 Duplex | 350 | S/D | AR98A-61 | 98 |

| 2652 Duplex | 600 | S/D | Not Available | 21 |

| National | Valve Size | S/D | Abrasion Resistant Stainless Steel Valve Units | Series |

|---|---|---|---|---|

| J-50-M, J-60-M, J-125-H, J-150-H, 60T-3M | 200 | S | AR05A-12 | 5 |

| J-50-M, J-60-M, J-125-H, J-150-H, 60T-3M | 200 | D | AR50A-02 | 50 |

| J-50-L, J-60-L, 60T-3L, 80T-3L | 250 | S | AR06A-09 | 6 |

| J-50-L, J-60-L, 60T-3L, 80T-3L | 250 | D | AR66A-02 | 66 |

| J-85-M, J-100-M, 100T-4M 130T-4M | 250 | S | AR06A-09 | 6 |

| J-85-M, J-100-M, 100T-4M 130T-4M | 250 | D | AR66A-02 | 66 |

| J-85-L, J-100-L, 100T-4L 130T-4L | 350 | S | AR98A-01 | 98 |

| J-85-L, J-100-L, 100T-4L 130T-4L | 350 | D | AR90A-02 | 90 |

| J-125-M, J-150-M, J-165-M, 165T-5M J-200-M, 200T-5M, 300Q-5M, J-250-M, J-275-M, 250T-5M | 300 | S | AR89A-07 | 89 |

| J-125-M, J-150-M, J-165-M, 165T-5M J-200-M, 200T-5M, 300Q-5M, J-250-M, J-275-M, 250T-5M | 300 | D | AR80A-01 | 80 |

| J-125-L, J-150-L, J-165-L, 165T-5L, J-250-L, J-275-L, 250T-5L, 300Q-5L, 200T-5L, J-200-L | 400 | S | AR10A-19 | 10 |

| J-125-L, J-150-L, J-165-L, 165T-5L, J-250-L, J-275-L, 250T-5L, 300Q-5L, 200T-5L, J-200-L | 400 | D | AR11A-04 | 11 |

| J-375-M, J-625-M, 430T-7M(3-1/2), 625Q-7M, JWS-340L | 350 | S | AR10A-19 | 10 |

| J-375-M, J-625-M, 430T-7M(3-1/2), 625Q-7M, JWS-340L | 350 | D | AR11A-04 | 11 |

| J-375-L, J-625-L, 625Q-7L, J-625-7L, 430T-7L | 550 | S | Not Available | 19 |

| J-375-L, J-625-L, 625Q-7L, J-625-7L, 430T-7L | 550 | D | Not Available | 19 |

| F-15-M | 150 | S/D | AR02A-02 | 2 |

| F-15-L, F-30-S | 175 | S/D | AR03A-08 | 3 |

| F-30-L, F-60-S (Serial #500 & Up) | 250 | S/D | AR06A-10 | 6 |

| F-60-S, (Serial #499 & Down) | 250 | S/D | AR06A-11 | 6 |

| F-90-S (Serial #299 & Down) | 300 | S/D | AR89A-03 | 89 |

| F-90-S (Serial #300 & Up) | 300 | S/D | AR89A-04 | 89 |

| F-90-L | 400 | S/D | AR10A-20 | 10 |

| D-50 Duplex | 400 | S/D | AR10A-01 | 10 |

| C-150 Duplex | 550 | S/D | Not Available | 21 |

| Union | Valve Size | S/D | Abrasion Resistant Stainless Steel Valve Units | Series |

|---|---|---|---|---|

| SX-3, DX-5, TX-10 1 1/2″ Cyl. (Plunger Size 1 1/8″ To 1 5/8″) | 150 | S/D | AR02A-12 | 2 |

| TD-50, TD-60, QD-100 1 1/8″ Cyl. | 175 | S/D | AR03A-12 | 3 |

| TD-50,TD-60, QD-100 1 3/4″ Cyl. | 200 | S/D | AR05A-29 | 5 |

| TD-50, TD-60, QD-100 2 1/2″ Cyl. | 250 | S/D | AR06A-21 | 6 |

| TD-120, QD-200 “B” CYL. | 250 | S/D | AR36A-18 | 36 |

| TD-120, QD-200 “C” CYL. | 400 | S/D | AR15A-01 | 15 |

| TD240,QD-400,QD-700 *5.50″ Flg f/ QD400 C Cylinder | 400 | S/D | AR10A-50 | 10 |

| TX-75 | 250 | S/D | AR98A-40 | 98 |

| TX-150 | 350 | S/D | AR98A-34 | 98 |

| TX-125, QX-300 | 400 | S/D | Not Available | 12 |

| TX-150L | 525 | S/D | Not Available | 25 |

| 5.5×3.5×5 (Threaded Seat) Duplex | 275 | S/D | AR04A-08 | 4 |

| 6.5×12 (Threaded Seat) Duplex | 275 | S/D | AR04A-09 | 4 |

| 6x4x6 (Threaded Seat) Duplex | 350 | S/D | AR98A-04 | 98 |

| 7×3.5×10 (Threaded Seat) Duplex | 300 | S/D | AR08A-14 | 8 |

| 10×7.5×12 (Threaded Seat) Duplex | 400 | S/D | AR10A-38 | 10 |

| Wheatley | Valve Size | S/D | Abrasion Resistant Stainless Steel Valve Units | Series |

|---|---|---|---|---|

| P-50, P-100, P-175, P-200 | 175 | S | AR03A-04 | 3 |

| P-50, P-100, P-175, P-200 | 175 | D | AR03A-03 | 3 |

| P-50A, P-100A, P-200A, 5P-200A, P-200B, T-230, T-225M/AL/AM/LS, 2S-1M/L, 5S-2M/L, 11D-2M/L, 22T-2M/L, 32T-2M/L, 31Q-2M/L | 175 | S/D | AR03A-04 | 3 |

| P-313, 5P-313, P-200-H, HP-200-H | 175 | S | AR02A-18 | 2 |

| P-313, 5P-313, P-200-H, HP-200-H | 225 | D | AR05A-34 | 5 |

| P-300, 5P-300 | 250 | S | AR04A-02 | 4 |

| P-300, 5P-300 | 175 | D | AR03A-04 | 3 |

| P-300A, 5P-300A | 225 | S | AR05A-13 | 5 |

| P-300A, 5P-300A | 175 | D | AR03A-04 | 3 |

| P-323, 5P-323, HP-125M, 59T-3M, 103Q-3M, 110Q-3M, T-365M, T-385M, Q-3115AM/MS | 225 | S/D | AR05A-13 | 5 |

| P-330, 5P-330 | 325 | S | AR08A-09 | 8 |

| P-330, 5P-330 | 250 | D | AR04A-02 | 4 |

| P-330A, 5P-330A, HP-125-L, 103Q-3L, 100Q-3L, T100-4, HP-100L, HP-115L, HP-165L, T140-4, HP-200L, T-4140L,133T-4L, Q-4240L, 101T-4L, 217Q-4L, 163Q-5L | 325 | S/D | AR08A-09 | 8 |

| P-364 | 225 | S | AR05A-13 | 5 |

| P-364 | 250 | D | AR04A-02 | 4 |

| HP100M, HP115AM, HP165M, HP115AM, HP165M, 101T-4M, HP200M, T4140M, Q-4240M, T100-3,163Q4M, T140-3, 103Q-3M, 110Q-3M, 133T-4M, 217Q4M | 250 | S/D | AR04A-02 | 4 |

| HP-100L, HP-165L, 101T-4L, 133T-4L, 163Q-4L, 217Q-4L, T100-4 | 325 | S/D | AR08A-09 | 8 |

| HP-160H, HP-225H, HP-250H, HP-360H, HP-375H, HP-600H, 184T-7H, 308T-7H, 543Q-7H, HP-300H, 133T-4H, T140-2 | 300 | S | AR89A-24 | 89 |

| HP-160H, HP-225H, HP-250H, HP-360H, HP-375H, HP-600H, 184T-7H, 308T-7H, 543Q-7H, HP-300H, 133T-4H, T140-2 | 300 | D | AR89A-13 | 80 |

| HP160M, HP225M, HP250M, HP300M, 133T4M, HP360M, HP375M, HP600M, 184T-7M, T140-3, 308T-7M, 543Q-7M, Q-7600M, T-7340M | 300 | S/D | AR98A-31 | 98 |

| HP-160L, HP-225L, HP-250L, HP-300L, 133T4L, HP-360L, HP-375L, HP-600L, 184T-7L, T140-4, 308T-7L, 543Q-7L, Q-7600L, 7340L | 400 | S/D | AR12A-31 | 12 |

| T4140M, Q4240M | 400 | S/D | AR04A-02 | 4 |

| T4140L, T4240L | 325 | S/D | AR08A-09 | 8 |

| P-610 | 250 | S | AR07A-20 | 7 |

| P-610 | 225 | D | AR05A-13 | 5 |

| P-610-B | 325 | S | AR08A-09 | 8 |

| P-610-B | 225 | D | AR05A-13 | 5 |

| P-630 | 400 | S | Not Available | 12 |

| P-630 | 250 | D | AR04A-02 | 4 |

| P-640 | 375 | S | Not Available | 17 |

| P-640 | 300 | D | AR09A-09 | 9 |

| P-640-A, P-540-A | 400 | S | AR12A-31 | 12 |

| P-640-A, P-540-A | 300 | D | AR98A-31 | 98 |

| P-650 | 400 | S/D | Not Available | 20 |

| QT-630 | 400 | S/D | Not Available | 12 |

| 3P-450 | 400 | S | Not Available | 12 |

| 5P-450 | 400 | S/D | Not Available | 12 |

| 535, 333, 33R, 1824 Duplex | 250 | S/D | AR04A-02 | 4 |

| 1024, 1324, 7024 Duplex | 350 | S/D | AR98A-09 | 98 |

| WBA Duplex | 350 | S | AR09A-27 | 9 |

| WBA Duplex | 350 | D | AR10A-30 | 10 |

| WBF Duplex | 400 | S/D | AR10A-30 | 10 |

| 1150, 2050, 2150, 2150-A, WBO, 6050-B, 7036-P Duplex | 400 | S/D | AR10A-24 | 10 |

| 7036, 6050, 5830 Duplex | 400 | S/D | Not Available | 12 |

| 1036DA, 5850DA Duplex | 400 | S/D | Not Available | 12 |

| WBC, WBD, WBL, 1570, 2070, 2170, 2170A, 2180, 2180A | 400 | S/D | Not Available | 12 |

| 7 1/2 x 10 Duplex | 400 | S/D | Not Available | 12 |