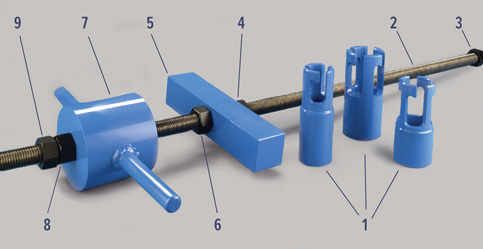

Valve Puller

All Triangle Pump Components valve units are designed for easy installation with minimum disassembly. When inspection shows that wear has occurred, however, proper maintenance such as replacing the valve disc, spring, and sleeve, or torquing studs, bolts, and locknuts may be required. We also recommend re-facing or reinstalling the seat to eliminate any ridges at the inner or outer edges.

Removing A Valve With The Valve Puller

To safely remove a pump valve, follow these steps: