In a perfect reciprocating pump system, suction and discharge valves should gently open and close as the plunger reaches its full stroke extension into the fluid end or full point of retreat back toward the power end. However, we all know we don’t live in a perfect world and this perfect functionality is never the reality. There is always some lag time in the opening with any model pump valve. The problem is – the more lag, the greater the problem for the pump.

For suction and discharge valves to function properly they must work in unison. The suction valve cannot open until the discharge valve is closed and vice versa. Valves open when enough pressure is exerted to overcome the weight of the valve member and the spring force pushing back against the valve member. Valves close mainly due to spring force.

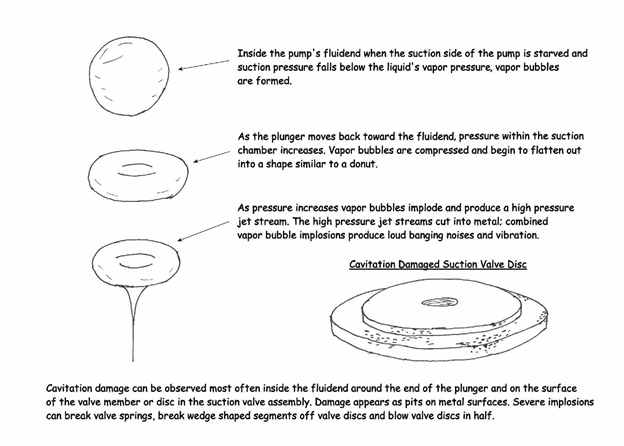

When these functions are not in balance, vibration and cavitation can occur (see figure 1).

Both are destructive to the pump, pump valves, plungers, and suction and discharge piping. The lag time followed by the sudden opening of the valve or almost violent closing creates a force akin to water hammer, but within the pump’s fluid end.

Vibration and cavitation, as related to pump valves, can occur:

Vibration and cavitation, as related to pump valves, can occur:

- When a heavy valve member is paired with too light of a spring. Obvious remedies are to match the spring rate with the weight of the valve member either by changing to a heavier spring or a lighter valve member – or both.

- Under conditions when there is low suction pressure (NPSH) and the valve has a spring that is too heavy. A lighter spring is called for.

- When there is too much seating surface to valve member surface making contact. This can cause the valve member to stick to the seating surface creating momentary lag. The phenomenon is similar to tightly placing the palms of both together and then pulling them apart. The momentary sticking sensation is the same as with a pump valve. This is due to poor pump valve design.

- It is common today for operators to run pumps at higher RPMs. Problems occur when the valve springs aren’t heavy enough to match the increased force within the fluid end. Solutions include substituting a heavier spring or adding an additional spring.

Obviously there can be other contributing factors besides the pump valves, such as poor suction and discharge piping design, blocked suction lines and so forth. However if the problem originates in the pump valves, these are the areas to begin your investigation.

Download our Suction System Problems and Prevention Techniques

If you would like to learn more about how our valves can curtail cavitation and keep your reciprocating plunger pump running smoothly for years to come, contact us today.